Feature

- Forming, wet pressing processes independently

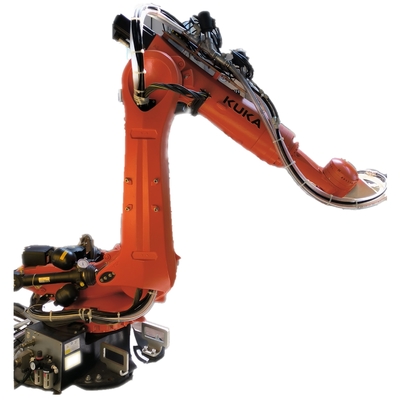

- Robot arms is optional to meet the requirement of customer

- Flexible machine setting, according to the automation requirement

- More choice on the layout design to match different plant size

- Low machine investment to start-up business

![]()

Application:

![]()